Step 1: laser print your layout on transparency film.

Step 2: Buy pre-treated photosensitive pc board:

Step 3: Cut a piece of the pc board to size.

Step 4: Using a “safelight” that won’t expose the board (a 40W incandescent bulb), peel off the protective white layer:

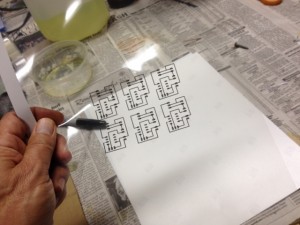

Step 5: Lay the pattern on the board (treated side up) and cover with an acrylic plate to hold it in place:

Step 6: Expose under a UV photo lamp for 5-8 minutes.

Step 7: UV light makes the exposed parts of the board susceptible to removal using NaOH solution. Place in a NaOH bath until the pattern becomes clearly visible. In my experiment last night this took about 30 seconds. Immediately rinse in a water bath to remove excess NaOH. The bottle says 1 part concentrated solution to 7 parts water. I got better results with a ratio of 1:10:

Step 8: Etch away the copper using equal parts 14% HCL and 3% H2O2. Takes 10-20 mins:

Step 9: Rinse in water and dry.